SC 320-4/1500; SC 320-4 MC/800; SC 200 DUO;SC 500 DUO

Designed for high speed, high rigidity and high reliability to ensure high productivity over a long service life. Rapid traverse rate of 15m/min and high speed turret indexing. High power spindle drive motor. All operation controlled from machine front. Designed to keep chips and coolant contained.

SC 260

Return to MZT FAM Home Page

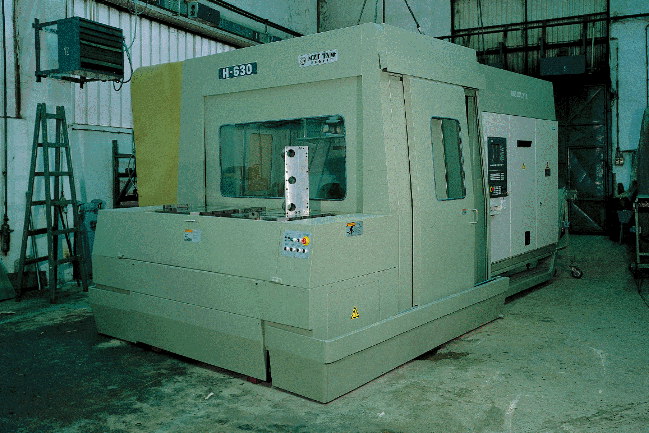

Horizontal and Vertical machining center packed with High-Tech. features for exceptional versatility. Advanced comprehensive factory automation systems. Rigid spindle-head designed for high-accuracy.Tool magazine capacities to meet any requirement. Wide range of pallet changer systems. Many features for automatic operation. Large work envelope.

H 630

Return to MZT FAM Home Page

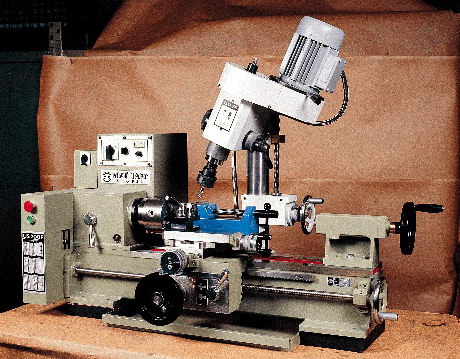

The universal lathes are suitable for machining parts in single and serial production with diameter range from 50 to 500 mm. They also have a wide range of metric,module,Whithworth and diametral pitch threads.

The up to date design and simple handling enables economic machining of the parts.

The high rigidity of the main spindle, set in highly precise bearings,enables high quality machining. The build-in microverter enables continious changing of the main spindle rotation. The yeald increase is achieved by applying the standard and optional accessories, i.e. chuck,rests,ram with fast exchanging tool holders, cooling device, centers, light installation, set of changeable gears for different threads etc.

US 200

Return to MZT FAM Home Page

Manufacture of molding tools. Manufacture of tools for blown glass containers with one or more dies and volume up to 5(l). Manufacture of special cutting tools. Manufacture of measurement gauges. Manufacture of pressing tools.

These are completly automatic machines for plastics wrapping material with capacity from 0.05 to 30 litres.

Machines are using extruder from F30/20D to F80/20D by which following materials may be proccesed(LDPE, HDPE, PVC, PP,PC ect.)

Extruders are driven by DC-motors, by which a fine regulation of the number of worm rotations.

Advantages of this machines is usage of high-quality electronic control as SIEMENS, OMRON with TOUCH SCREEN monitor.

Driving systems of the tools may use pneumatics or hidraulics, depending on the size of wrapping material.

Hidraulic system uses proportional technique which enables high-quality and soundless working.

Our production assortment offers machines for labeling, printing, filling, testing and palleting of the plastics wrapping material.

All a.m. machines may be delivered individually or in a automatic lines.

Our long-range expirience as producers of these machines is a sufficient guarantee for the quality of the machines which are very simple for usage and maintenance.

We are ready to cooperate with our buyers and to design our machines in accordiance with your needs and special requests, depending on the type of the product (wrapping material) which is to be manufactured.

We also offer complete engineering refeering the branch of plastics wrapping material as well as filling and packing.

At the end we would like to add that we provide service and spare parts.

These are intended for manufacturing of parts for middle and large series in automobile industry, industry for hidraulic and pneumatic components, electric industry etc.

Wide range of typical units enables qualitative solutions and high precise for different mechanic operations.

Depending on the extent of a serie we offer machines intended for determinate mechanic operations for large series as well as high flexibile machines with CNC equipment, automatic change of tool etc., for smaller series and kindred machining parts.

Our team of experts based upon your requirements will offer most sophisticated solution.

This machines are used for milling machining in a single or a serial production of plate and box shaped parts. The rigid and firm construction of the machine as well as the qualitative and stable placing in bearing of the working spindle, by using the proper and qualitative ball bearings ensures proper and qualitative and productive milling even at working under harder conditions. The milling machines completely satisfies the up-to-date requirements for machining as well as the economical utilization of cutting tools made of hing speed steel and hard metal utilizing the optimum cutting speeds.

Produces various types of box and rotating machine parts and units, in accordiance with the design of the customer or own design.

Possesses various machinery concepted for small and large serial production, where high-quality machines have significant role, as well as production control by CNC and coordinate measuring machines. These prerequisites enable manufacturing of any product who would satisfy any customer world wide.

Services for milling,scraping, grinding, CNC centers, horizontal milling-drilling, CNC turning, universal turning, round grinding, honing and deep drilling.

Precision control by the coordinate measuring machines:

-LEITZ, PMM 181010

-TAYLOR HOBSON, TALYCENTA

-TAYLOR HOBSON, TALYVEL